3D PRINTING: A REVIEW

Abstract

Author(s): Shubham Bairagi, Mr.Kuldeep Vinchurkar* Rahul Kushwah, Dr.Neelam Balekar

This review article is a summary of organ and tissue showing 3D printing. Processing 3D of appropriate shape, structure and size is the most difficult and challenging job for tissue engineering Tissu e organ printer is being presented by us which is exclusively designed for constructing similar shapes and sizes, which is possible by using biodegradable polymers while printing cell-laden hydrogels. The right shape of the tissue can be attained and it is possible by representing clinical imaging data as computer model of the anatomical defect and also to interpret the model into various programs that are used to control the movement of the printer nozzles. The incorporation of micro channels into the tissue constructs facilitated diffusion of nutrients to printed cells, and as a result it overcomes the diffusion limit of 100-200 µm for cell survival in engineered tissues. We demonstrated the ability of ITOP by making mandible and calvarial bones, cartilages and skeletal muscles. The ITOP can be used in future in developing or making of more complex tissues and organs of solid nature.

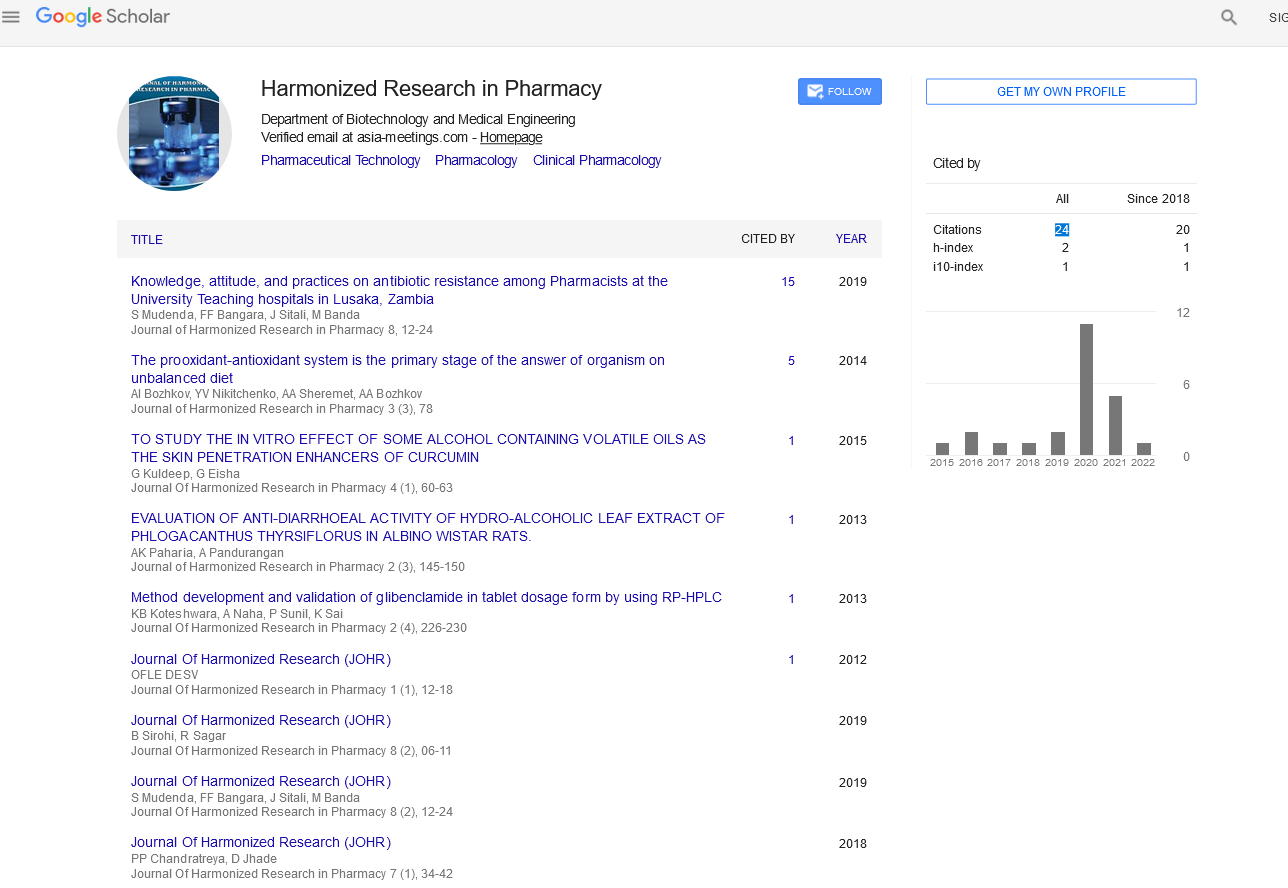

Google Scholar citation report

Citations : 147

Journal of Harmonized Research in Pharmacy received 147 citations as per google scholar report