APPLICATION OF NEURAL NETWORK TO REDUCE THE MACHINING OPTIMIZATION

Abstract

Author(s): Ashim Mukherjee, Amit Kachawaha

For efficient use of machine tools, selection of machining process and determination of optimal cutting parameters (speed, feed and depth of cut) are required. The aim of this paper is to di scover the role of these parameters is to prediction in milling operations by using artificial neural networks and Taguchi design of experiment. The study was conducted by using milling machine with fine type carbide tool with twin cutting edge. The experimental data is later used to predict output data by using artificial neural network.

+44 193 554 8010

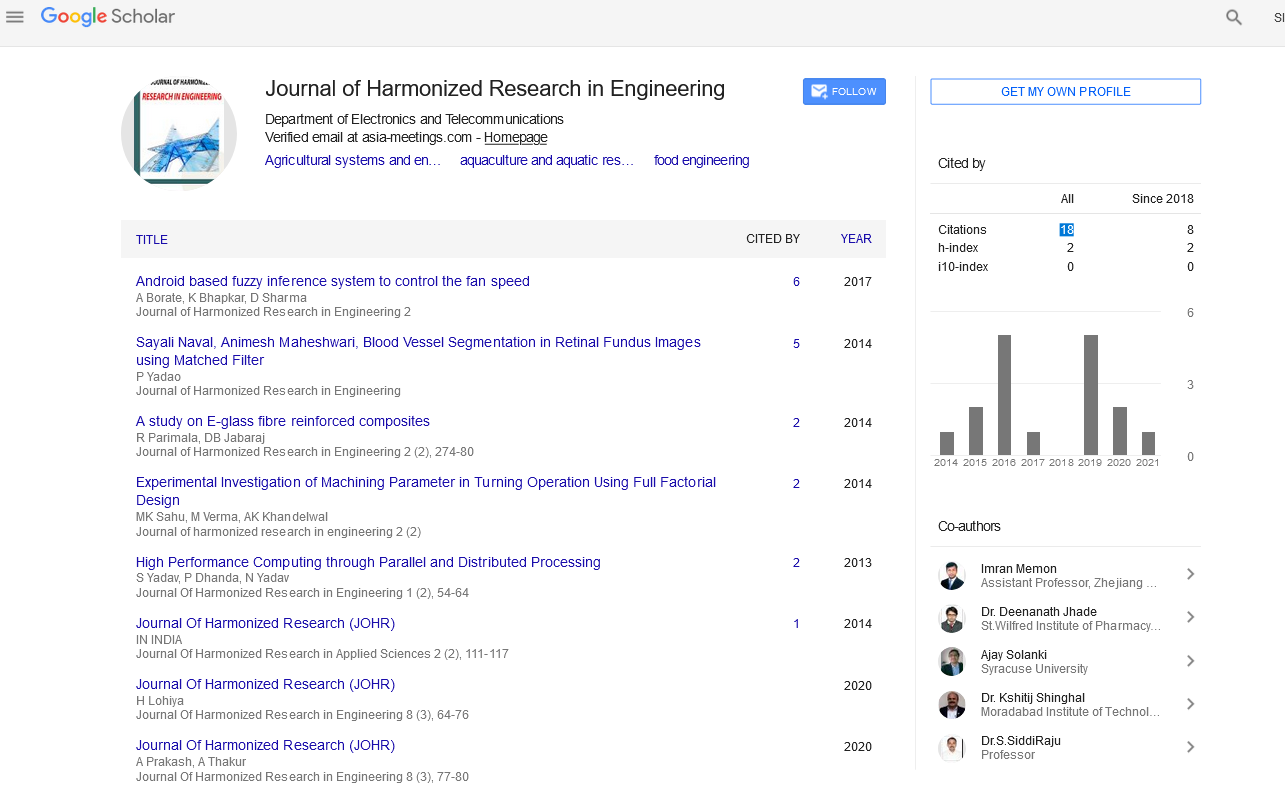

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report