DEVELOPMENT OF CASSAVA (MANIHOT) CHIPPING MACHINE USING ELECTRIC MOTOR CUM MANUAL OPERATION

Abstract

Author(s): J.O. Awulu*, J. Audu and Y.M. Jibril

An electric motor cum manually operated cassava (Manihot Esculenta crantz) chipping machine was developed and its performance evaluated. The purpose is to increase surface area which aid in quick dry ing of cassava chips. Local available materials were used for the fabrication. This machine consist majorly of a hopper, chipping blades, transmission shaft, collection box, electric motor, a handle and frame. The machine was evaluated using 300-400 rpm speeds. The varying speeds were carried out using different diameters of pulleys. Analysis of variance was used to determine the significant effect in efficiency, speed of operation, chip size and time at p < 0.05. Duncan’s New Multiple Range Test (p<0.05) was used to analyze the difference in the various parameters investigated. The results indicate that speed has significant effect on the mass of well chipped cassava and its efficiency, but has no significant effect on the chipping time at 95% confident level for the dual power types investigated. The dimensions of the chips obtained were in the range of 10-20mm for electric motor and above 20mm for manual. As the operational speed increased from 300-400rpm, there was a decrease in efficiency of the dual power types investigated. 300rpm gave the highest efficiency of 86.7% and 83.12% for electric motor and manual turning operation respectively and better chipping geometry than other speeds. The machine has a feeding capacity of 209kg/hr. This machine is simple to operate and maintain for small and medium scale farmers.

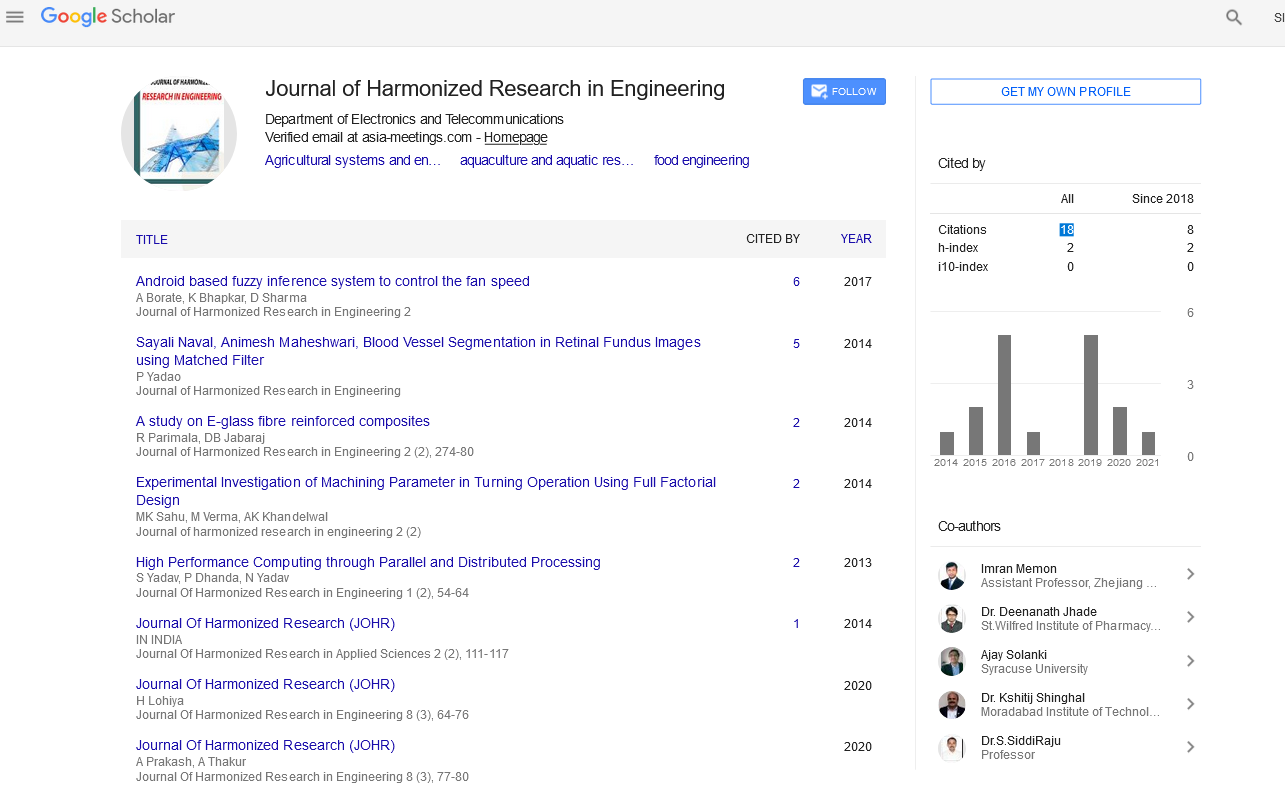

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report