EXPERIMENTAL ANALYSIS ON ALUMINIUM COMPOSITE MATERIAL WITH FLY ASH

Abstract

Author(s): Rupendra Kumar Sinha, Sharda Pratap Shrivas, Ashish Kumar Khandelwal

Consisting of two or more physically and chemically distinct phases will make composite material. The composite generally has superior characteristics than those of each of the individual c omponents. There has been an increasing interest in composites containing low density and low cost reinforcements. Usually the reinforcing component is distributed in the continuous or matrix component. Fly ash is a very fine material which is produced by burning of pulverized coal in boilers of thermal power plants. The fly ash is sent to ash ponds in the form of slurry with water since it is economical. This fly ash being finer and lighter than river sand has lower settlement rate, which can be increased by adding a suitable polymer to the ash slurry in the pond. Among various reinforced materials used, fly ash is one of the most inexpensive and low density reinforcement available in large quantities as waste product during combustion of coal in thermal power plants as well as in the brick factory and rice mill. It is therefore expected that the incorporation of fly ash particles in aluminium alloy will promote yet another use of this low-cost waste by-product and, at the same time, has the potential for conserving energy intensive aluminium and thereby, reducing the cost of aluminium products. The present investigation has been focused on the utilization of abundantly available industrial and domestic waste fly-ash in useful manner by dispersing it into aluminium to produce composites by casting method. In this work two type of casting has to be obtain by MMC and compare their mechanical properties in between them. Keywords- Reinforcements, pulverized coal, fly ash, MMC, casting

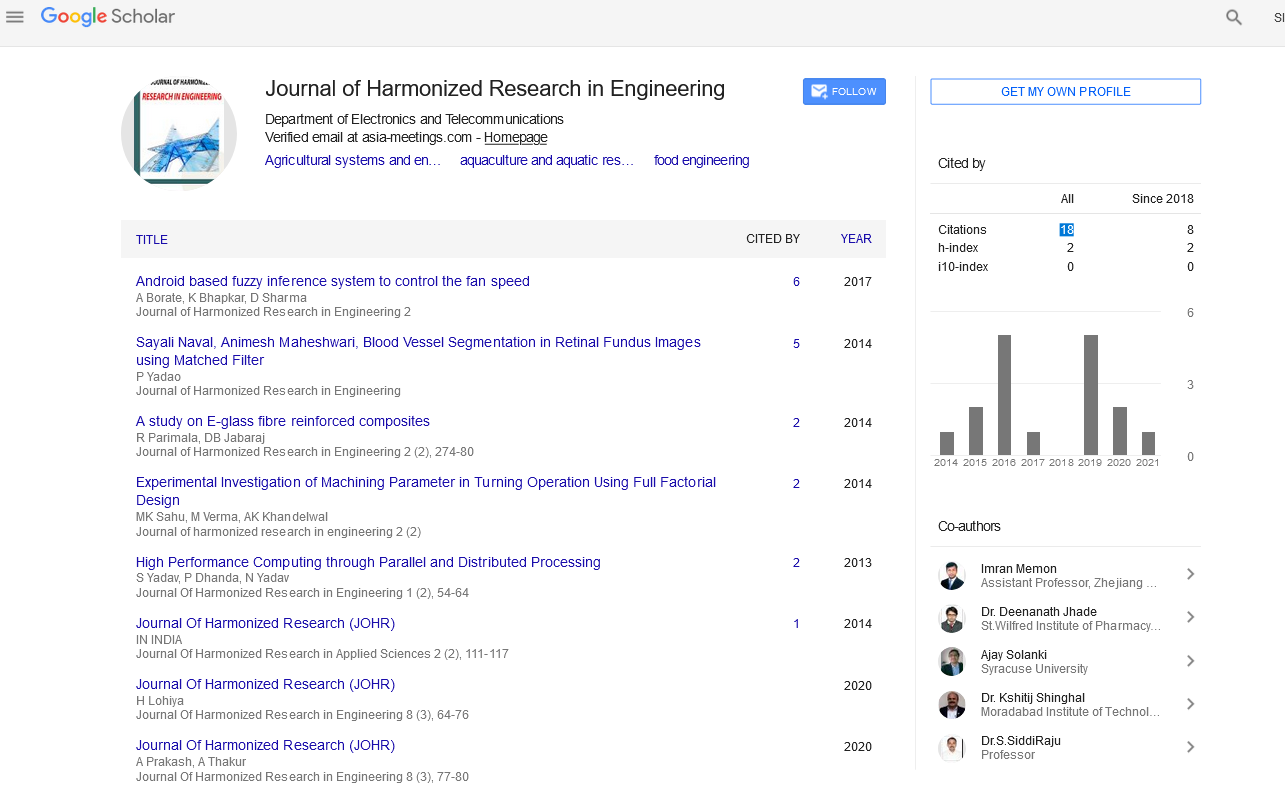

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report