OPTIMIZATION OF PRESSURE DIE CASTING PROCESS PARAMETERS BY TOPSIS METHOD

Abstract

Author(s): Mukesh Kumar Upadhyay, Mihir Kumar Pandey

TOPSIS has developed a methodology for the application of designed experiments, including a practitioner’s handbook. This procedure has taken the design of experiments from the exclusive world of the statistician and brought it more fully into the world of manufacturing. Experiment carried out on design of experiment characterized by different survey on the basis of Temperature, Force exerted with Type of casting process on aluminum alloy that solidify and investigation the defects of shrinkage and porosity due to gases passed in casting process. In this work defects initiation and progression have been analyzed in order to identify the factors causing these very high residual stresses that often produce shrinkage and porosity spread throughout the casting.The defects were found on every square centimeter by microscope and then take their ordinary. The best productivities were obtained on the basis of results of confirmation experiments reveal that TOPSIS method can efficientlyoptimize an optimal combination of the process parameters.

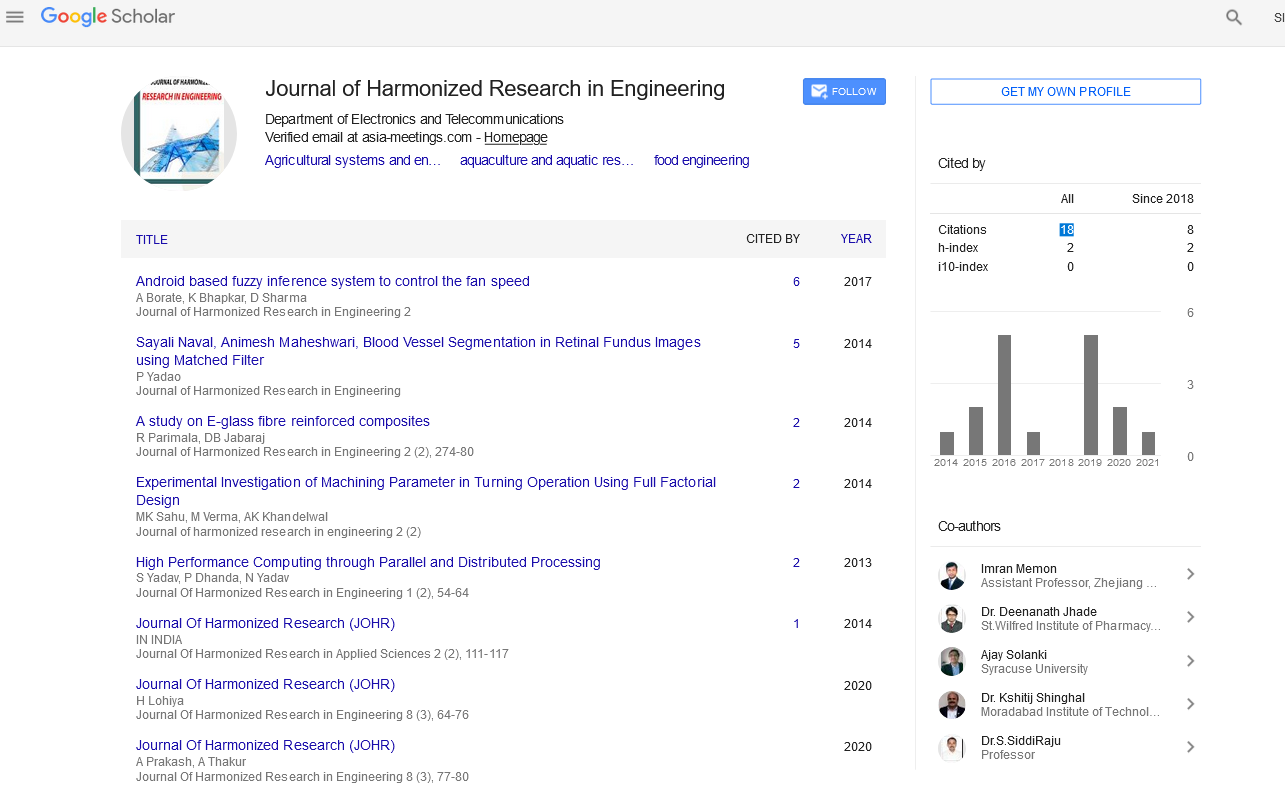

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report