REDUCE THE TIME SPAN OF JOB SHOP BY SCHEDULING METHOD

Abstract

Author(s): Neeraj Chandra and Amit Kumar Kachhawaha

Conventional methods of solving scheduling problems based on priority rules still result schedules, sometimes, with significant idle times. To optimize these, this thesis model the problem of a flow shop scheduling with the objective of minimizing the makes pan. This paper model the problem of a flow shop scheduling with the objective of minimizing the makes pan. The objective is to minimize the make span of batch-processing machines in a flow shop. The processing times and the sizes of the jobs are known and non-identical. The processing time of a batch is the longest processing time among all the jobs in that batch. Consequently, comparison based on Gupta’s heuristics, RA heuristic’s, Palmer’s heuristics, CDS heuristics are proposed in this work. Gantt chart was generated to verify the effectiveness of the proposed approaches.

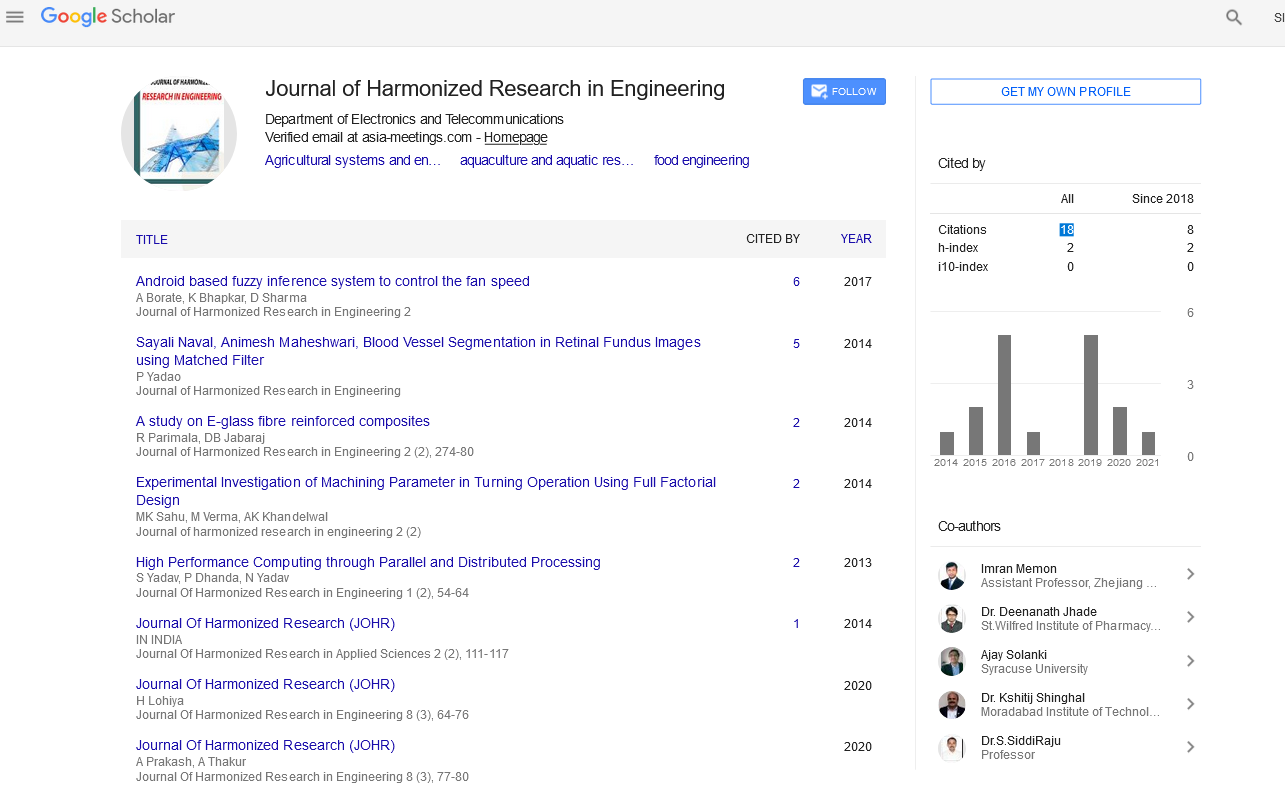

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report