Perspective - (2021) Volume 9, Issue 2

APPLICATIONS OF 3D PRINTING IN BONE TISSUE ENGINEERING

Liu James*Received: Dec 06, 2021

Description

Bone tissue engineering is an interdisciplinary approach that uses a combination of cells and biomaterials to restore the required function of tissue. Scaffolding is an important part of bone tissue engineering. These are 3D structures that provide a template for cell adhesion in the formation of bone tissue. There are several important parameters that define the performance of one scaffold. These include pore volume, pore size, chemistry, and mechanical strength. It is created after understanding the bone mechanics, bone structure, and tissue formation of new functional bone tissue. There are various methods that have been widely used in the production of porous bone. These methods are chemical foaming, lyophilisation, solvent casting, and foam gel.

3D printing was first introduced to create prototypes for developing products in specific industries. This technology is part of Additive Manufacturing (AM), which creates layer- by-layer parts from a 3D Computer-Aided Design (CAD) model. When printing the framework with polyjet printing, the parameters are optimized to achieve the appropriate quality, such as powder fluidity, binder dripping amount, powder pack dentistry, and layer thickness. There are many different types of 3D printing technology, each of which can print parts and is material-specific. These technologies use materials such as gypsum powder, plastics, resins, aluminides, ceramics, sand, metals, polyetheretherketone (PEEK), and graphene to manufacture the required parts. Inkjet 3D printing technology offers a breakthrough in bone tissue engineering. It facilitates the necessary distribution of scaffold cells. We also use bio-inks for efficient regeneration and component reconstruction.

3D printing technology is making advances in bone regenerative medicine by creating living tissues and organs. 3D bone tissue can be easily created using Bioink to meet your challenges. This bio ink is in the form of hydrogel and a viscous liquid. Bioink is used to create 3D structures loaded with cells. 3D printing and bio-inks have been successfully used in the production of bone tissue, taking into account various parameters for the development of specific bio- inks, such as printability and mechanical integrity.

This new field is aimed at treating bone diseases. It plays an important role in cell adhesion, differentiation, proliferation, migration, and formation of calcified bone tissue. Bone is composed of cancellous bone, but cortical bone has two different structures. The cancellous bone is the inner part of the bone and the cortex is the outer part of the bone. Together, these two have the ability to heal themselves to restore normal behaviour. There are also options for autologous and allogeneic transplants that allow bone tissue engineering to restore and improve its function.

Conclusion

Bone tissue engineering is an innovative approach used directly to repair bone defects/tissues for transplantation. Biomaterials play an important role in supporting cell regeneration and tissue regeneration. Additive Manufacturing is a disruptive innovation that uses different types of scanning, printing, and associated software support. It is used to create bespoke scaffolds of complex shapes from photographs in less time and cost. It is successfully used in bone tissue engineering to repair and regenerate bone. It gives a basic knowledge of bone biology and its development.

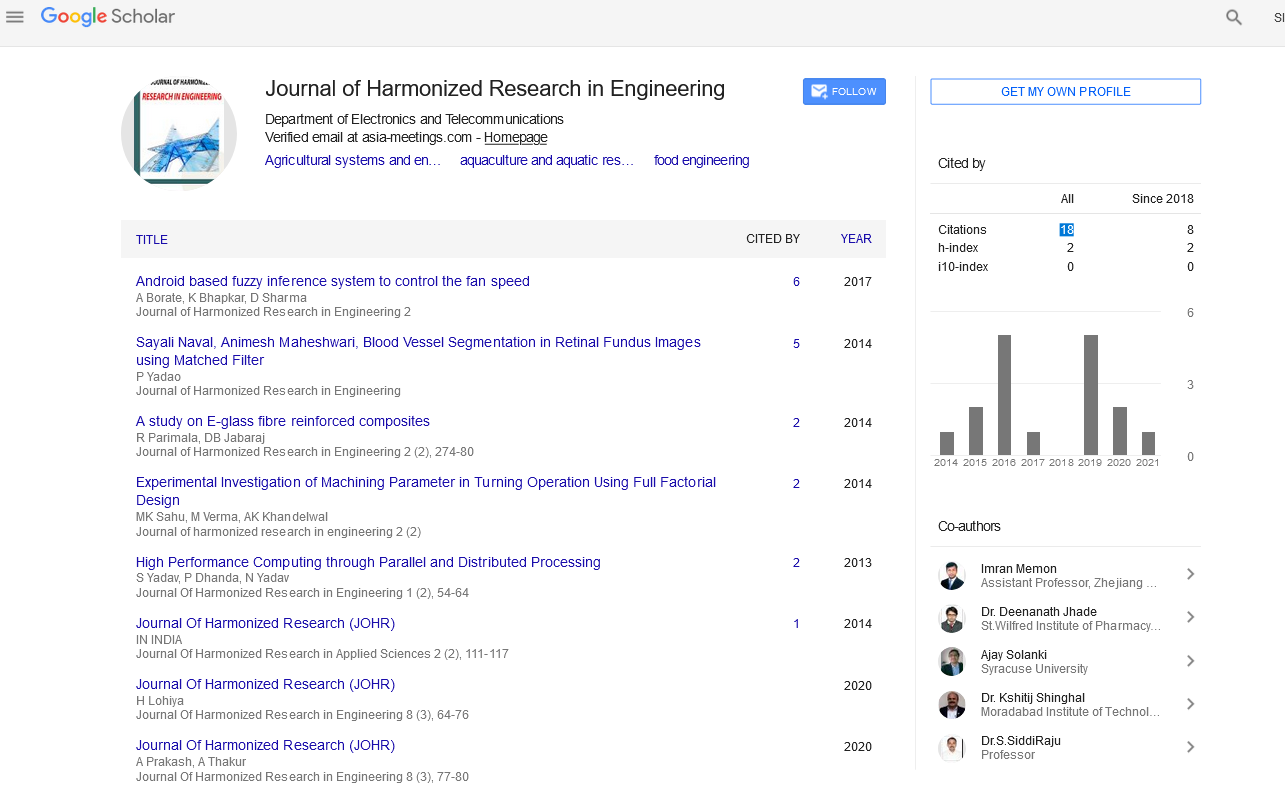

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report