Short Communication - (2022) Volume 10, Issue 1

CRUCIAL WAYS AND KEY CHALLENGES IN USING LIVING CELLS TO OBTAIN THE DESIRED PRODUCT

Beck Barrett*Received: Mar 02, 2022, Manuscript No. JHRE-22-62064; Editor assigned: Mar 07, 2022, Pre QC No. JHRE-22-62064(PQ); Reviewed: Mar 21, 2022, QC No. JHRE-22-62064; Revised: Mar 28, 2022, Manuscript No. JHRE-22-62064(R); Published: Apr 07, 2022, DOI: 10.30876/2347-7393.22.10.196

Description

With the development of increasingly advanced biotherapies and other critical products, bioprocessing is a key part of manufacturing and bringing these curatives and products to people, bioprocessing is getting more important than ever [1]. From vaccines and cell curatives to food and biofuels, bioprocessing provides numerous benefits to society however it can be challenging and expensive.

Still, there are several new technologies and techniques aiming to break these issues and help make bioprocessing more effective and less precious, some of the fundamentals of bioprocessing as well as an overview of recent trends particularly related to the medicinal and medical industries.

Bioprocessing is the creation of useful products through the use of a living thing generally cells or cell factors, contagions, or an entire organism, end products can be anything from biofuels produced from algae, or antibiotics created from earth, similar as penicillin, beer produced from yeast is another illustration of bioprocessing. Given the diversity of operations for bioprocessing and the complexity of the way involved, this field requires proficiency in numerous areas of wisdom including chemistry, biochemistry, biology, microbiology, and chemical engineering.

Crucial way in bioprocessing

Bioprocessing involves two main parts upstream bioprocessing technology and downstream bioprocessing technology. The upstream part involves the early stages of bioprocessing include correlating the identification of the organism to be produced, optimizing the conditions it requires to grow, and also growing and collecting this organism [2]. With biopharmaceuticals specifically, the upstream process includes isolating the cell line to be produced, growing those cells at the scale needed for the final product, and also harvesting those cells.

Downstream bioprocesses technology includes the after stages of product and involves purifying the cells or other organisms collected at the end of the upstream stage to produce a final product that meets strict safety and quality norms [3].

Bioprocess engineering is another crucial aspect of bioprocessing that involves optimizing the terrain or system in which the organism resides to ensure it can produce the required product at the scale and quality needed, but at the smallest possible cost, bioprocess engineers are thus critical to any industry making use of natural products or biomaterials [4].

Key challenges in bioprocessing and recent solutions

Though the COVID-19 pandemic has brought more attention to bioprocessing’s task in the development of vaccines, it also presented challenges to the medical and pharmaceutical industries. Companies in these fields faced supply chain dislocations, shortages of key accoutrements, and had to manage with new COVID-19 safety measures that limited the number of people able to work in their facilities.

Still, positives also came out of the COVID-19 situation with companies sharing resources, making better connections with their suppliers, and adopting new technologies quickly than they will prior to the pandemic.

In general, the biggest challenges in bioprocessing technology is especially when it comes to developing and producing bio therapeutics and vaccines, are time and cost [5]. Companies are always searching for ways to shorten the length of time it takes from discovering a medicine to manufacturing and shipping that medicine. Bettering cell culture media phrasings is another crucial challenge in cell therapy product in particular. Supporting technologies, finding the right partner to ensure quality, and the use of artificial intelligence will be key results.

Thermo Fisher Scientifics, is a concept that point out that in some substantiated cell curatives for cancer, the challenging workflows needed to produce similar treatments are a hedge to their wider use, Allogenic approaches to similar curatives can help conquer these challenges with cell culture media playing a key part in maintaining cell quality when producing these treatments on a large scale.

Another tough, time-intensive challenge in the bio-pharma industry is finding high quality cell lines and automating the process of isolating single cells using microfluidics in one result that can save companies a great deal of time and plutocrat. In addition to microfluidics, automation in single use bioprocessing technologies and their wider use throughout the entire bioprocessing workflow will probably be a trend going forward due to the needs of individualized drug.

While wise perpetration of similar technologies is certain to help make bioprocessing more effective and cost effective, strong partnerships and a collaborative spirit between companies, their clients, and others in the assiduity will be just as important to ensure that those depending on bioprocessing can manage both current challenges and those that arise in the future.

References

- Tripathi NK, Shrivastava A. Recent developments in bioprocessing of recombinant proteins: expression hosts and process development. Front. Bioeng. Biotechnol. 2019;7:420.

[CrossRef], [Google Scholar], [PubMed]

- Randek J, Mandenius CF. On-line soft sensing in upstream bioprocessing. Crit. Rev. Biotechnol. 2018;38(1):106-21.

[CrossRef], [Google Scholar], [PubMed]

- Chen SW, Zhang W. Current trends and challenges in the downstream purification of bispecific antibodies. Antib. Ther. 2021;4(2):73-88.

[CrossRef], [Google Scholar], [PubMed]

- Schewe H, Mirata MA, Schrader J. Bioprocess engineering for microbial synthesis and conversion of isoprenoids. Adv Biochem Eng Biotechnol. 2015:251-286.

[CrossRef], [Google Scholar], [PubMed]

- Paterson P, Meurice F, Stanberry LR, Glismann S, Rosenthal SL, Larson HJ. Vaccine hesitancy and healthcare providers. Vaccine. 2016;34(52):6700-6706.

[CrossRef], [Google Scholar], [PubMed]

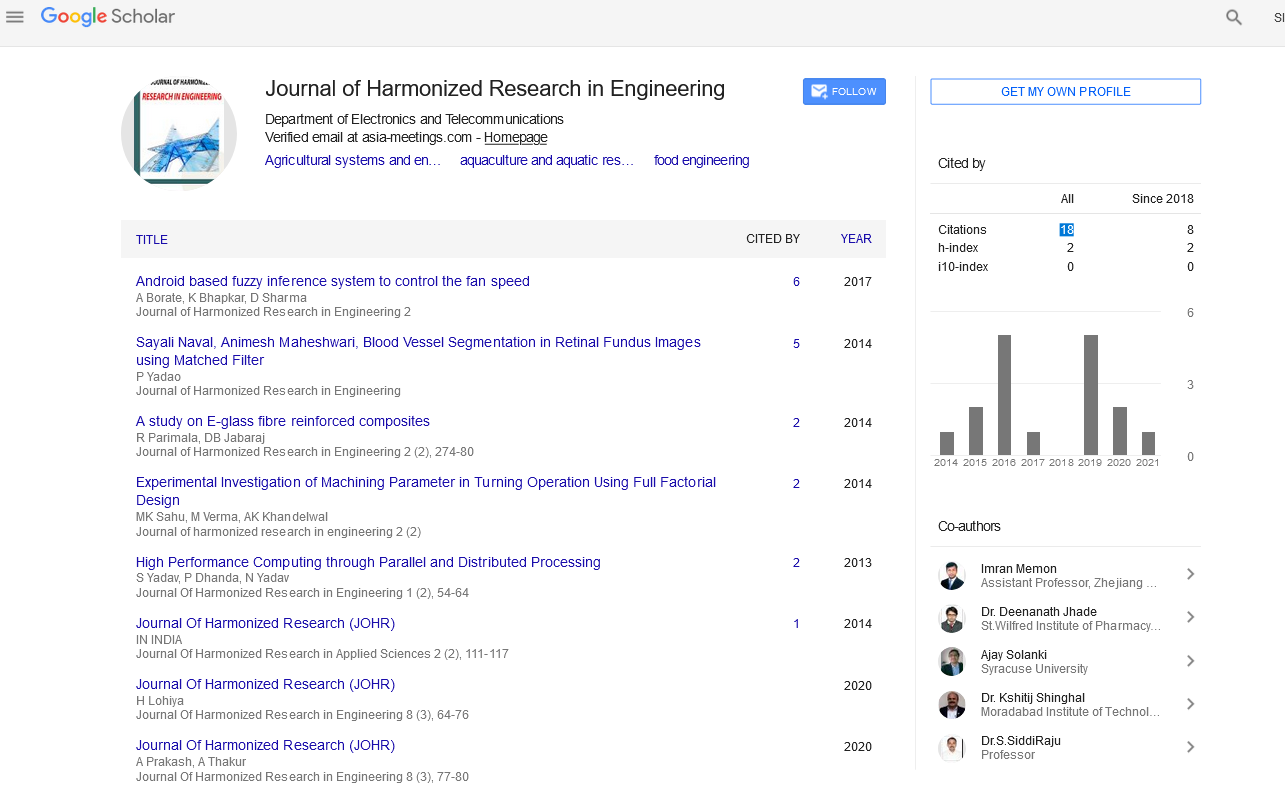

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report